Volvo series (10kw-3000kw)Technical Specifications

| Model | Brand | Engine Model | Engine Normal Power (KW) | Speed Control | Engine Brand | Emission Standards | Rated voltage (V) | Rated current (A) | Power factor | Frequency (HZ) | Speed (r/min) | Dimensions (mm) | Weight (KG) |

| COMLER80KW | COMLER | TAD580VE | 86 | High pressure common rail | Volvo | China National IV | 400/230 | 144.3 | 0.8 | 50 | 1500 | 2050*1000*1900 | 2200 |

| COMLER100KW | COMLER | TAD582VE | 118 | High pressure common rail | Volvo | China National IV | 400/230 | 180.4 | 0.8 | 50 | 1500 | 2050*1000*1900 | 2400 |

| COMLER120KW | COMLER | TAD880VE | 135 | High pressure common rail | Volvo | China National IV | 400/230 | 216.5 | 0.8 | 50 | 1500 | 2180*1000*2050 | 3000 |

| COMLER150KW | COMLER | TAD882VE | 163 | High pressure common rail | Volvo | China National IV | 400/230 | 270.6 | 0.8 | 50 | 1500 | 2180*1000*2050 | 3100 |

| COMLER200KW | COMLER | TAD1181VE | 223 | High pressure common rail | Volvo | China National IV | 400/230 | 360.9 | 0.8 | 50 | 1500 | 2600*1000*2350 | 3300 |

| COMLER250KW | COMLER | TAD1382VE | 267 | High pressure common rail | Volvo | China National IV | 400/230 | 451.1 | 0.8 | 50 | 1500 | 2600*1140*2550 | 3800 |

| COMLER300KW | COMLER | TAD1385VE | 339 | High pressure common rail | Volvo | China National IV | 400/230 | 541.3 | 0.8 | 50 | 1500 | 2600*1140*2550 | 4100 |

| COMLER260KW | COMLER | TAD1351GE | 279 | Electronic control unit pump | Volvo | China National III | 400/230 | 469.1 | 0.8 | 50 | 1500 | 3100*1100*1900 | 3100 |

| COMLER280KW | COMLER | TAD1352GE | 314 | Electronic control unit pump | Volvo | China National III | 400/230 | 505.2 | 0.8 | 50 | 1500 | 3100*1100*1900 | 3150 |

| COMLER300KW | COMLER | TAD1354GE | 328 | Electronic control unit pump | Volvo | China National III | 400/230 | 541.3 | 0.8 | 50 | 1500 | 3100*1100*1900 | 3200 |

| COMLER330KW | COMLER | TAD1355GE | 355 | Electronic control unit pump | Volvo | China National III | 400/230 | 595.4 | 0.8 | 50 | 1500 | 3100*1100*1900 | 3300 |

| COMLER360KW | COMLER | TAD1650GE | 393 | Electronic control unit pump | Volvo | China National III | 400/230 | 649.5 | 0.8 | 50 | 1500 | 3150*1200*2100 | 4100 |

| COMLER400KW | COMLER | TAD1651GE | 430 | Electronic control unit pump | Volvo | China National III | 400/230 | 721.7 | 0.8 | 50 | 1500 | 3150*1200*2100 | 4200 |

| COMLER480KW | COMLER | TWD1652GE | 505 | Electronic control unit pump | Volvo | China National III | 400/230 | 866.1 | 0.8 | 50 | 1500 | 3550*1600*2180 | 4800 |

| COMLER500KW | COMLER | TWD1653GE | 547 | Electronic control unit pump | Volvo | China National III | 400/230 | 902.1 | 0.8 | 50 | 1500 | 3550*1600*2180 | 5100 |

| COMLER550KW | COMLER | TWD1645GE | 595 | Electronic control unit pump | Volvo | China National III | 400/230 | 992.3 | 0.8 | 50 | 1500 | 3550*1600*2180 | 5200 |

Volvo Penta - Established in 1907 as a subsidiary of Sweden's Volvo Group, Volvo Penta is a leading manufacturer of marine and industrial engines as well as complete power systems. Consistently upholding the core values of quality, safety, and environmental protection, Volvo Penta has earned widespread recognition and popularity among customers worldwide through its superior products and comprehensive services. Since establishing its Chinese branch in 1996, Volvo Penta has introduced tens of thousands of its engines to China, which are widely used in power generation equipment, oilfield machinery, construction machinery, port equipment, mining machinery, commercial vessels, official vessels, and yachts. Volvo has formed a long-term strategic partnership with Comler.

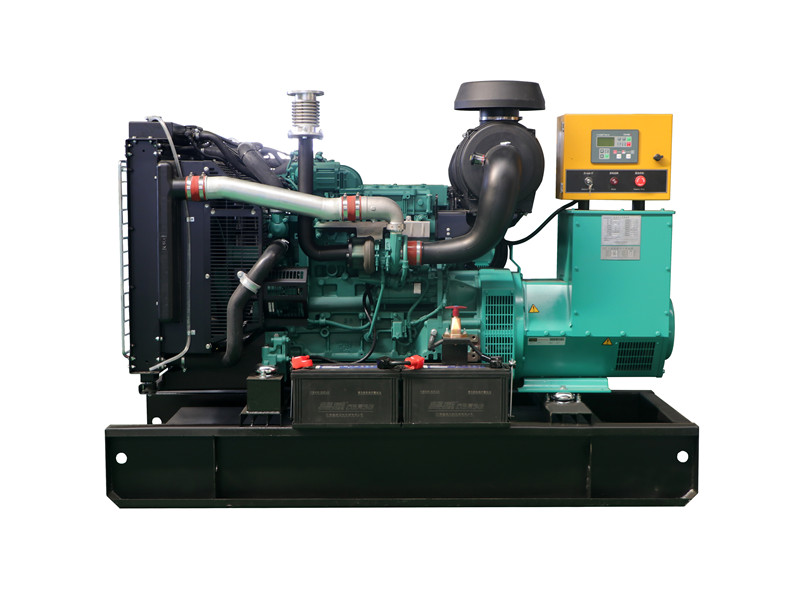

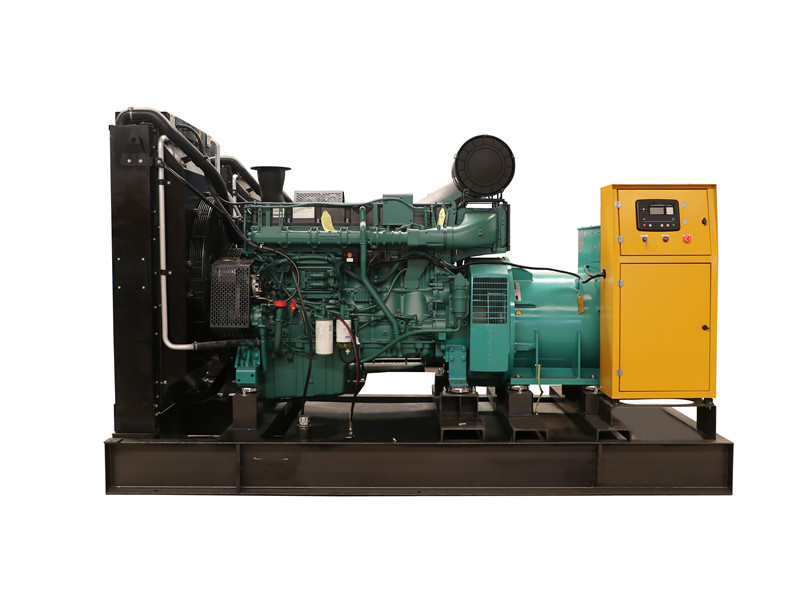

COMLER diesel generator sets use high-performance COMLER generators, Volvo engines and other configurations. The superior overall design, production and assembly are more in line with standard technical requirements. Constant pressure control systems are configured according to standard requirements. It has the characteristics of more convenient operation, good efficiency, lower fuel consumption, longer service life, low carbon and environmental protection. The perfect pre-sales, in-sales, after-sales and maintenance service system and respected brand will provide customers with better services and contribute to the overall technological development and progress of China's electromechanical industry.

鲁公网安备37083002370842号

鲁公网安备37083002370842号