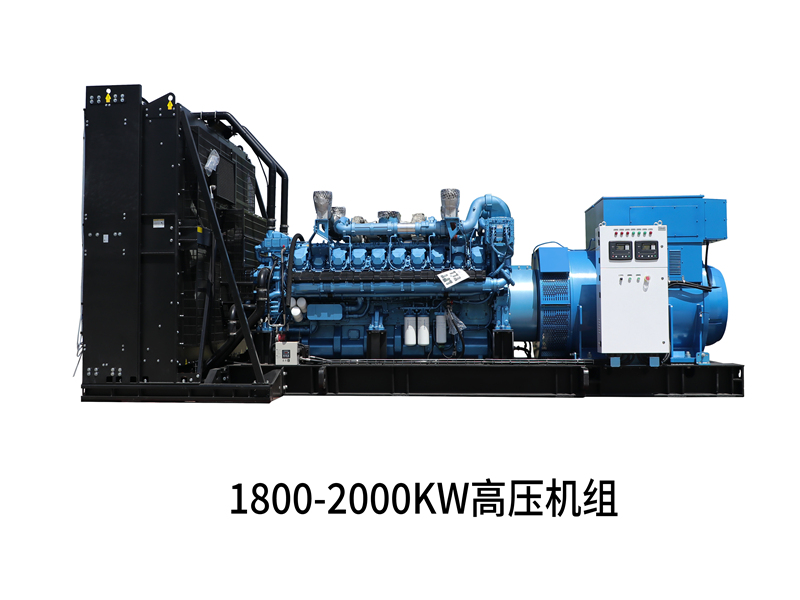

COMLER High Voltage Generator Set Power Supply System (Engineer XNL)

The COMLER high-voltage generator set has high precision voltage regulation , excellent dynamic performance, small voltage waveform distortion, high efficiency, compact structure, easy maintenance, reliable operation, long service life, and good economic performance. Due to the high output voltage and low output current of the unit, along with the characteristic of low power loss during power transmission, so that it is highly suitable for long-distance power transmission. The high-voltage power supply system can directly connect to high-voltage loads, save large sum of investment costs for power supply and distribution system equipment, and is more convenient to use.

Power supply system characteristic of COMLER high-voltage generator set

The COMLER series of high-voltage power generation units can be operated either as a single unit for power supply, or as multiple units forming an independent power grid (parallel operation) to supply power to the load, or as a single unit or multiple units connected through the parallel grid connection management system to be integrated with the mains power supply to form a power grid for supplying power to the load.

Application of COMLER high-voltage generator set power supply system

The COMLER high-voltage power generator set have been widely used, especially in applications where the bigger capacity and the long transmission distance. The high-voltage diesel power generator set has these obvious advantages such as large capacity, long-distance power supply, strong reliability, and reasonable structure for the power distribution system. The high-voltage diesel power generator set has been widely used in more fields such as mining, metallurgy, data centers, ports, and airports. The intelligent control system saves energy for parallel connection and large unnecessary investments for power supply and distribution systems. Especially the characteristic of high voltage and low current determines the advantage of long-distance transmission of high-voltage generators.

Data centre application of COMLER high-voltage generator set

The COMLER high-voltage power generator set is the key technical solution for large and super-large data centers to meet the demand for large-capacity backup power. By means of increasing the voltage level and effectively overcomes the problems of high transmission loss, huge cable usage, excessive space occupation, and complex parallel connection for low-voltage systems with high power operation. Although its initial investment and system complexity are relatively high, and the operation and maintenance requirements are more professional, the long-term operational efficiency (low loss), space savings, and system architecture simplification (compared to massive low-voltage parallel connections) make it irreplaceable in meeting the high power density, high reliability, and high energy efficiency requirements of modern data centers. When choosing a high-voltage solution, a comprehensive technical and economic comparison (TCO analysis) must be conducted, and the design, equipment selection, installation quality, and professional operation and maintenance management of the high-voltage system must be given high attention.

Control system characteristic of COMLER high-voltage generator set

1.Functions and Features - Construction: The high-voltage generator set mainly consists of a common base frame, high-voltage generator, engine, cooler (water tank), high-voltage switch cabinet, low-voltage control panel, power cabinet (optional), PT cabinet (selected based on function).

2.Powerful communication capabilities include an 10M/100M adaptive industrial Ethernet port, and also equipped with 2 serial ports for easy communication with other intelligent devices. The communication protocols for each serial port and the Ethernet ports can be independently configured. Complete communication protocols; the network layer supports TCE protocol and UDP protocol. The application layer supports CDT92, IEC870-101.103, 104 and other protocols.

3. High-voltage switch cabinet: The switch cabinet adopts the COMLER-KYN28A-12 type cabinet, in accordance with GB/T 3906-2020 《3.6KV - 40.5KV AC METAL ENCLOSED SWITCHGEAR AND CONTROL SYSTEMS》 GB 1984-2024 《HIGH VOLTAGE AC CIRCUIT BREAKERS》, and GB 1985-2023 《HIGH VOLTAGE AC ISOLATING SWITCHES AND GROUNDING SWITCHES》. It is equipped with high-voltage circuit breakers and CT, PT, and relay protection devices (integrated protection). It has obtained the qualified certification report approved by the national electrical product quality supervision and inspection authority. This system follows the general fully decentralized design. The system integrates protection, remote measurement, remote signaling, remote control, and other functions. It has overcurrent, instantaneous protection, low voltage PT and CT disconnection, winding grounding, etc. protection functions. It measures three-phase voltage, three-phase current; active power, reactive power, power factor, frequency, zero-sequence current, etc. It is equipped with anti-fouling, lightning protection devices. It also has a low-voltage control cabinet, which improves the safety factor of the switch cabinet. |

|

4.PT cabinet (option): This is a voltage transformer cabinet. In high-voltage power distribution, due to the extremely high voltage, it cannot be directly connected to secondary equipment. Therefore, a voltage transformer is needed for conversion. Generally, 10KV voltage is converted to 100V or 220V, and then connected to protection devices, metering devices and etc. |

|

5.Power cabinet (optional) supplies control power to the high-voltage switch cabinet. The specifications include DC24V, DC48V, DC110V, DC220V; Characteristics of the DC panel control system ● The main monitoring system adopts a 320*240 LCD with Chinese menu display and touchscreen operation. ● The monitoring system adopts a modular building block structure. Multiple detection power supplies are controlled separately, and the internal components are connected through an RS485 bus. ● Battery inspection and insulation selection can be configured. ● Our company's 5A and above modules can be optionally equipped to form the system, with flexible configuration. ● It supports all wiring schemes (including three charging machines, dual battery groups, and bus sectioning). ● It can support dual groups of 18/112 or 9/56 batteries for inspection. ● It can support two sections of bus insulation branch detection, with up to 120 channels per section. ● The main monitoring provides RS232/RS485 interfaces with built-in RTU, CDT, and MODBUS communication protocols, and can be connected to the power station automation system. |

|

鲁公网安备37083002370842号

鲁公网安备37083002370842号